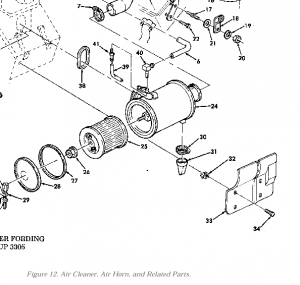

The screws attaching the air cleaner shield 2540-01-196-4726 [2540011964726] (Fig 12, Item 34) to the body in conjunction with shield, expansion 5340-01-208-8688 [5340012088688] are listed as SCREW,TAPPING #10-16 X 1/2 5305-00-058-1082 [5305000581082].

This can easily be upgraded with a stainless screw (Search “#10 X 3/4″ Stainless Indented Hex Washer Head Screw”) on Amazon or your favorite auction site.

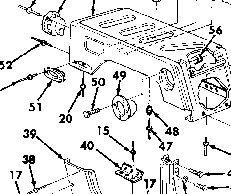

This same screw can be used as a substitute to mount the fuel tank filler neck, which specifically requires a 3/4″ length #10 5305-01-264-5874 [5305012645874] (Fig 199, Item 50).

NOTE: Although the call out for the expansion screw is for a 1/2″ length, there is adequate room to permit use of the 3/4″ length. Additionally, the requirement for 16 TPI isn’t relevant because it is essentially self-threading into nylon. The call out for the filler neck does require 12 TPI (because they thread into Tinnerman nuts), so purchase screws that meet this requirement and substitute for the 16 TPI thread. There is no reason to purchase different screws for each of these applications.