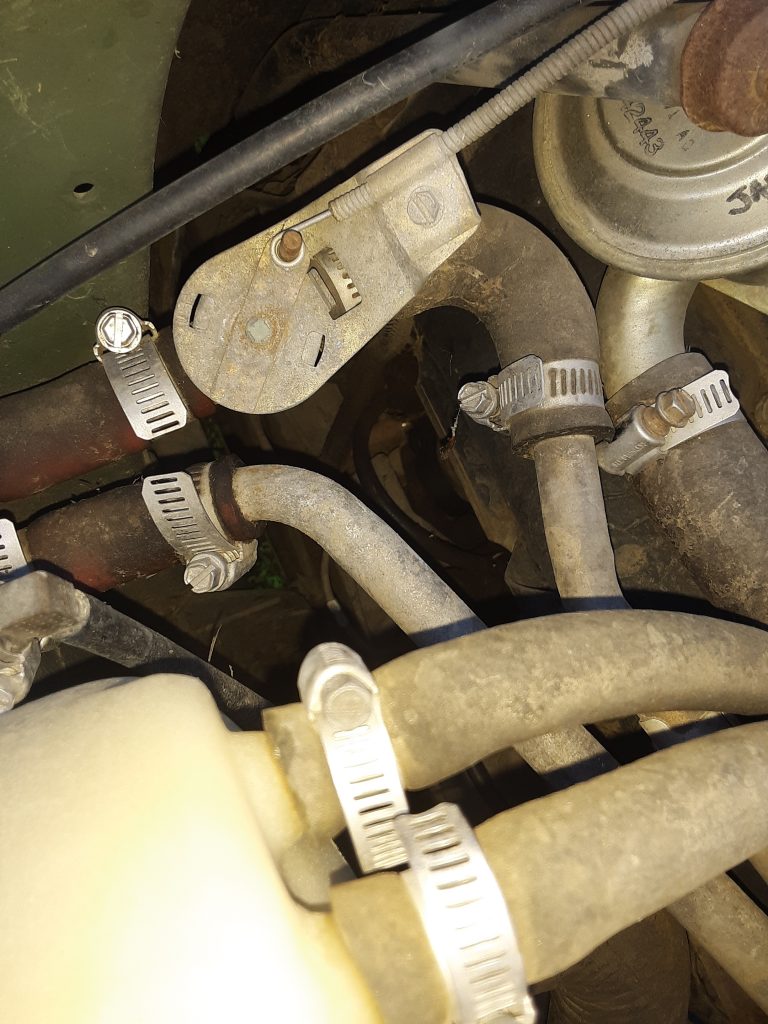

As we are replacing the 30-some year old hose and tubing with new, we need to access the fording valve to remove and replace the hoses. The below picture shows the hoses attached to the fording valve.

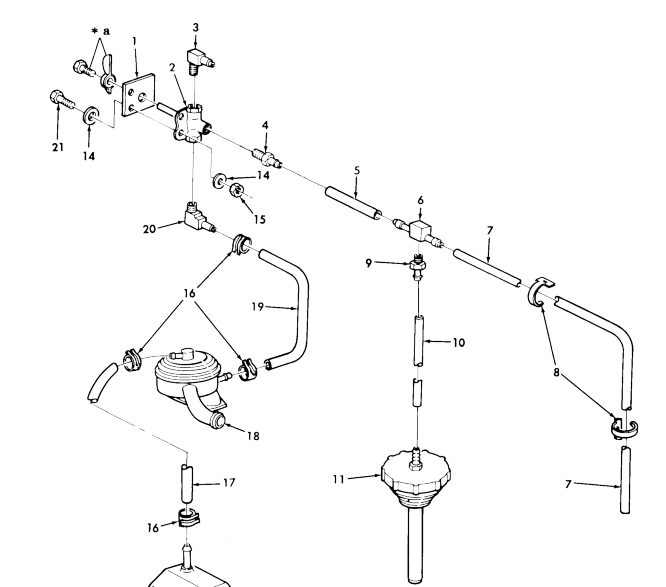

Both the upper and the middle tubings are called out as P/N CPR104420-1, while the bottom hose is called out as P/N RB1450-1-4IDX1-20D. As discussed in an earlier post, the CPR104420-1 can be interchanged with 1/4″ air brake tubing, such as Eaton Synflex®. Similarly, we have determined that although not a direct interchange, we could use either 1/4″ silicone hose or 1/4″ SAE J30R9 hose (fuel injection hose). For this application, even though the silicone hose has a much higher temperature rating, we had concern about abrasion on the hose so we substituted the J30R9 hose instead of the silicone. We do however, believe that the silicone hose would be more than acceptable as a substitute under most circumstances.

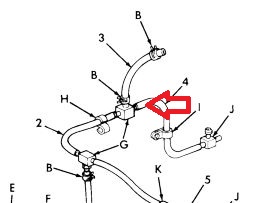

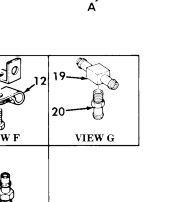

The parts manual shows an exploded view of the hoses and tubing that connect to the fording valve.

As shown above, the fording valve 4820-01-192-8030 [4820011928030] (Item 2) has three hoses connected to it. The lower hose goes to the lower fitting on the DWF (Deep Water Fording) CDR valve. The middle tubing goes to a line running across the cowling and tees into the vent line from the power steering pump cap. Although this is considered a special cap for DWF applications 2590-01-192-4425 [2590011924425], it is simply a standard power steering cap with a 1/8″ nipple adapter screwed into a hole in the center of the cap.

We have diagrammed the middle hose connection (Item 7) and fording valve top connection (Item 3). to view the diagram, please refer to this updated post.