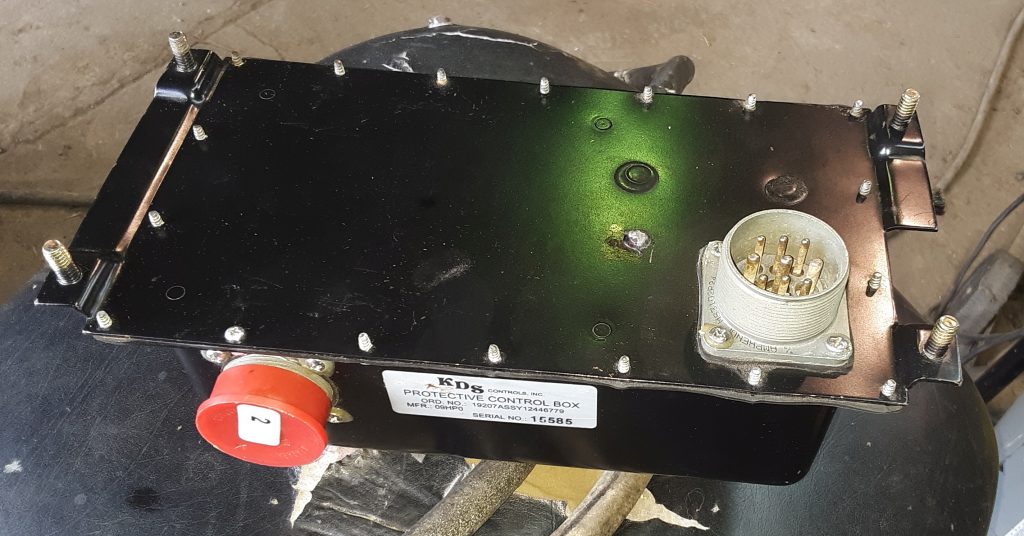

For our M1038, we obtained a mid-series control box, and a corresponding controller. The control box was in unused condition, and its connectors show indications that it has never been connected.

We located a controller that corresponds to the controller, but it had sustained some cosmetic damage.

Information on this controller 19207ASSY12446779 is scant. From what we can determine it was used on the M1113, and is similar to what was used on the M1114. (The M1113 used studs, as on this box, while the M1114 was threaded where the studs are).

It may also be referred to as a “silver label.” To make it clear, these are not EESS boxes. These boxes have been used on trucks up to the m115x, and are the generation between the old yellow/green label ones & the EESS. They are apparently a generation newer than the yellow label control boxes.

We have been cautioned that the operation of this box may make the “wait light” fail to light at higher ambient temperatures, but that is simply because it is not necessary to cycle the glow plugs.

Additionally, we have been cautioned that should a control box fail, there is a possibility that a vehicle fire may result. We will be installing a battery cut-off and will be testing the box before sending the vehicle out the door to reduce the potential for vehicle fire.

We have read good reviews on these boxes and that they are relatively reliable. However, if we note any issues we will reach out to an appropriate vendor for a newer generation control box and controller.