As discussed in a previous post, We removed the shunt and coated the entire interior of the battery box with the rubberized undercoating to protect the aluminum against corrosion from battery acid.

Solutions, Upgrades, and Parts Interchange for HMMWVs

As discussed in a previous post, We removed the shunt and coated the entire interior of the battery box with the rubberized undercoating to protect the aluminum against corrosion from battery acid.

In preparation for installation of two new 6TL batteries to power the M1038, we removed the battery hold downs and tray to see the extent of acid damage on the aluminum.

Although there was extensive corrosion evident, the CARC seemed to provide a lot of protection from the acid. After spending considerable hours scraping, wire brushing and using a “scruffing” pad on a small air grinder, we applied several passes of baking soda and water to neutralize any remaining acid.

After thoroughly flushing and drying the surface, etching primer was applied and let dry. We debated about final coating and went with rubberized undercoating. This material is definitely acid resistant. And it appears that the box may have been originally coated with rubberized undercoating from the Marines.

We will next remove the shunt and mask off the entire battery box to be coated with the rubberized undercoating.

It seems that most people fail to understand the difficulty of repairing or the time and expense to repair damaged transmission cooling lines. Both the lines in our M1038 and from our new powerplant were damaged, and unusable.

We could have just substituted hose for the lines. However, tubing is far sturdier, and rated for higher pressures. Consequently, tubing is less likely to fail than a long length of hose. Arguably, there is some cooling effect to be accomplished just from the +/- 20 feet of line.

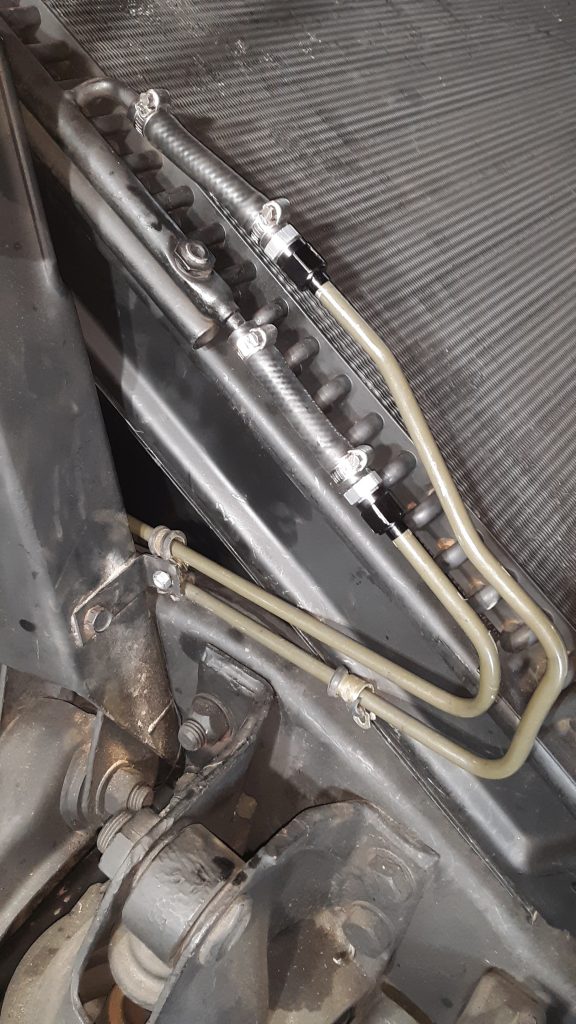

We determined that it would be virtually impossible to install factory cooling lines without removing the cooling stack and possibly even the powertrain. As a result, we used 3/8″ brake tubing and made our own.

We fabricated our cooling lines in two pieces (each line) that joins at the frame near the idler arm. This allowed us to have the complex bends on the front section, and allows for it to be somewhat easily installed. We do not have a 3/8″ beading tool — If we did, we would simply have beaded the ends. However, using a Ridgid 41162 377 flaring tool (which provides the proper 37 degree angle for AN fittings) and used Russell -6 AN tube sleeves and nuts to connect an AN to 3/8″ hose barb. This ensures a leak-free connection.

Although the transmission pressure through the cooler only reaches a maximum of 30 p.s.i., we were still concerned about preventing leaks between the hose and the tubing without having a bead.

Although the AN connectors are not cheap, we already owned the Ridgid flaring tool, and the cost of the fittings was considerably less than a beading tool.

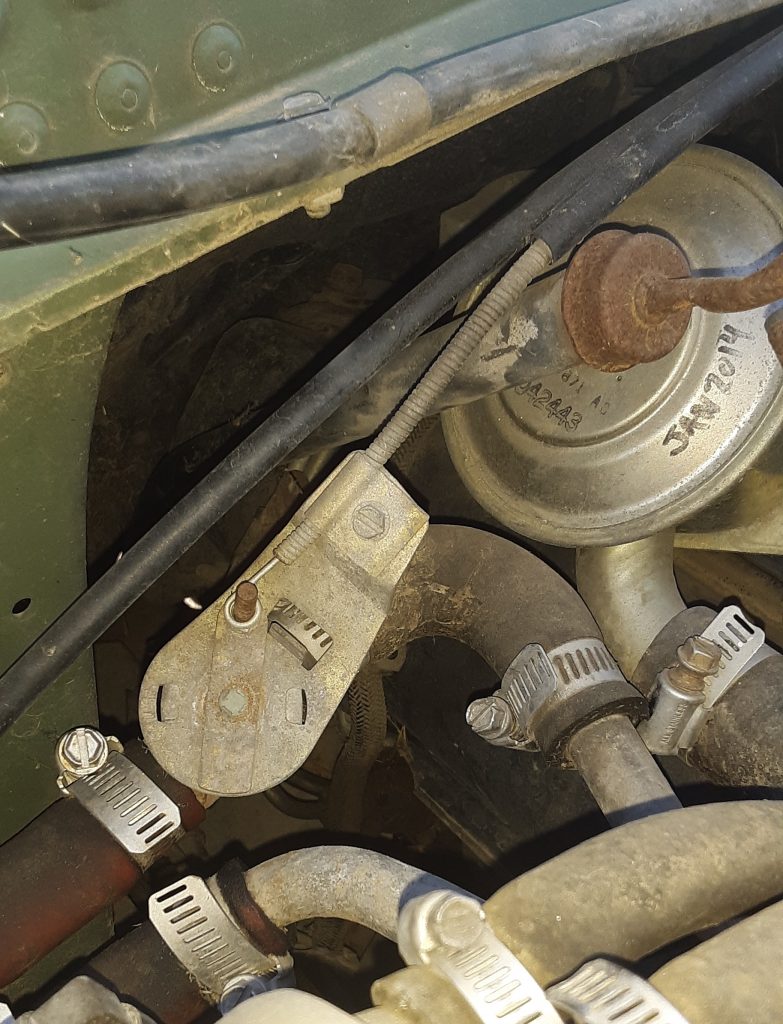

The Heater Control Valve 4820-01-189-2107 [4820011892107] (AMG 12339966) was missing from our vehicle. We researched the different aftermarket valves available and were able to locate a replacement: Four Seasons P/N 74828.

This appears dimensionally identical to one in an M998:

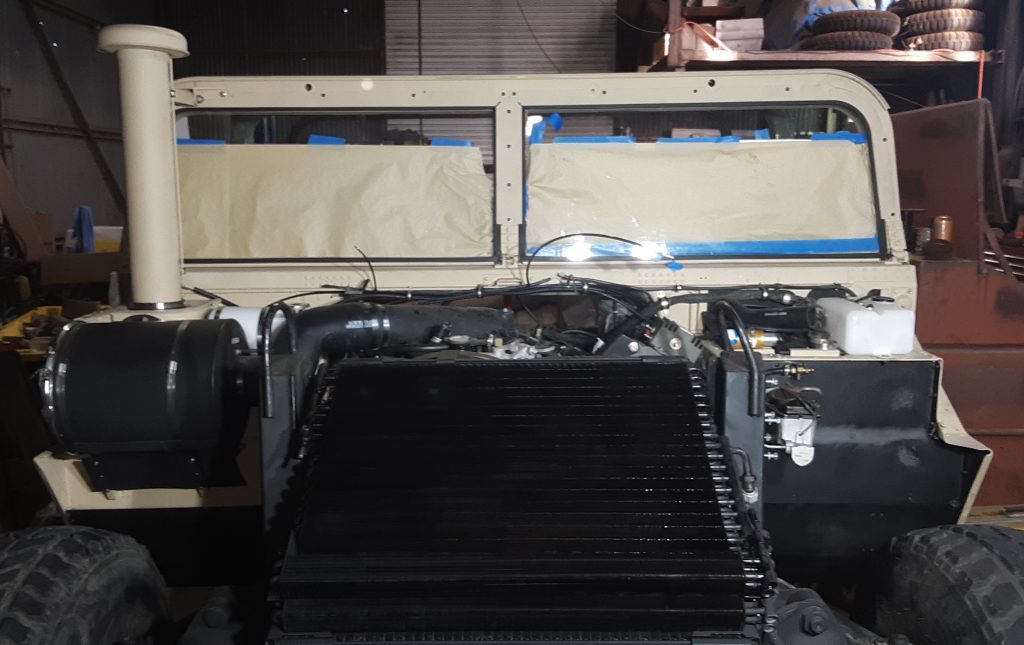

After the fasteners finally came in, we were able to assemble the cooling stack. Although we had attached the shroud to the radiator last week, we were finally able to fasten the oil/transmission cooler to the radiator, and install the power steering/hydraulic cooler over that.

As we have the later version radiator side mounts, we were able to precisely align the shroud to provide for optimum cooling. We were able to connect one of the two oil cooler lines, but will have to loosen the cushion clamps and re-orient the hose so we can connect to the fittings.

We will connect the power steering cooler after all lines have been connected from the pump to the brake unit, winch, and fan clutch. Similarly, as the transmission cooling lines were not serviceable, we will be making replacement lines out of 3/8″ brake tubing with AN adapters to 3/8″ hose. We will post on this once it gets underway.

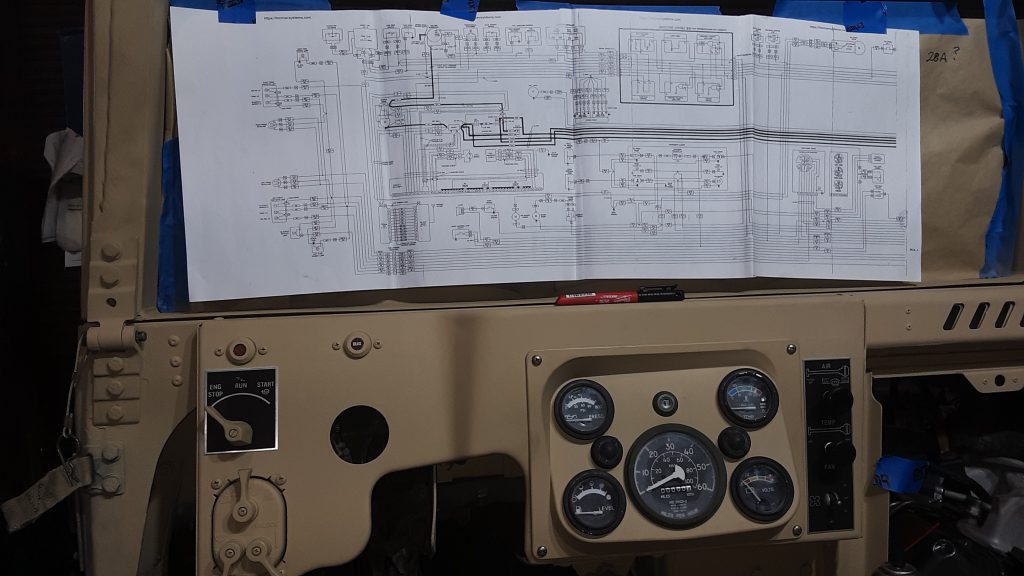

As this HMMWV did not have a dash or gauges installed, we had to identify each wire by number from the wiring diagram. We put tape on each wire and marked where it belonged. We found it simplest to tape the wiring diagram to the windshield to assist in wire location identification.

Through this process, we located where a 3 wire bundle had been cut off. Through the process of elimination, it appears that these wires are for the headlight dimmer switch. We will have to fabricate a new section which will involve soldering and splicing to the existing harness using waterproof marine heatshrink tube..

Once the Deep Water Fording (DWF) system has been installed, it is important to test the system for leaks.

Instructions for testing may be found in the “Instructions for Installation of Deep Water Fording Kit” at Section 3-14. The testing consists essentially of:

Notes on this test: 1) If there is only a slight leak, testing at 3.5 p.s.i. might pass the 1 minute test, whereas testing at 2.5 p.s.i. would fail the test. 2) It is best to conduct the test in a quiet area so that any leaks can be heard. 3) We recommend use of hand pump only, not a compressor or regulated air source. 4) We suggest making a low pressure leakdown tester as described here. 5) Application of excessive air pressure will likely “blow out,” dislodge or otherwise damage seals in the transmission, transfer case, differentials and gear hubs. Use of other than a hand pump could potentially cause damage in the thousands of dollars to repair.

Our initial testing went well. The tube to the power steering pump had to be removed and blocked because the cap did not seal well enough. After identifying this as a leak point, air was re-applied and was heard leaking into the engine.

As the only point for air to enter the engine would be the vent on the fuel pump, we suspect the fuel pump has a leak into the crankcase. We will first remove the vent line from the fuel pump and test again. If we are able to maintain pressure with that line plugged, we will have to replace the pump.

Our HMMWV failed the 1 minute test, and allows us to diagnose leak points, and potentially catch a fuel into crankcase or fuel into air filter situation.

We will update in a new post as to our further testing. We also want to further examine the venting circuit to ensure that the selector valve should be set to “vent” when testing at the CDR valve.

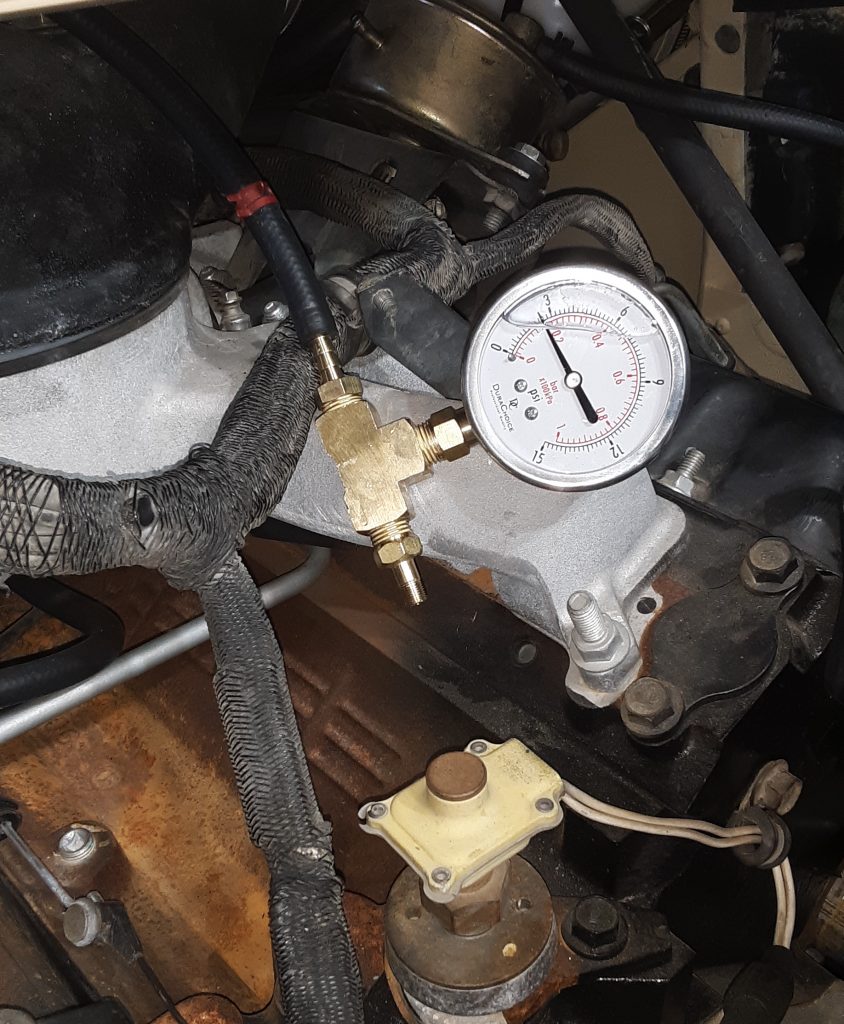

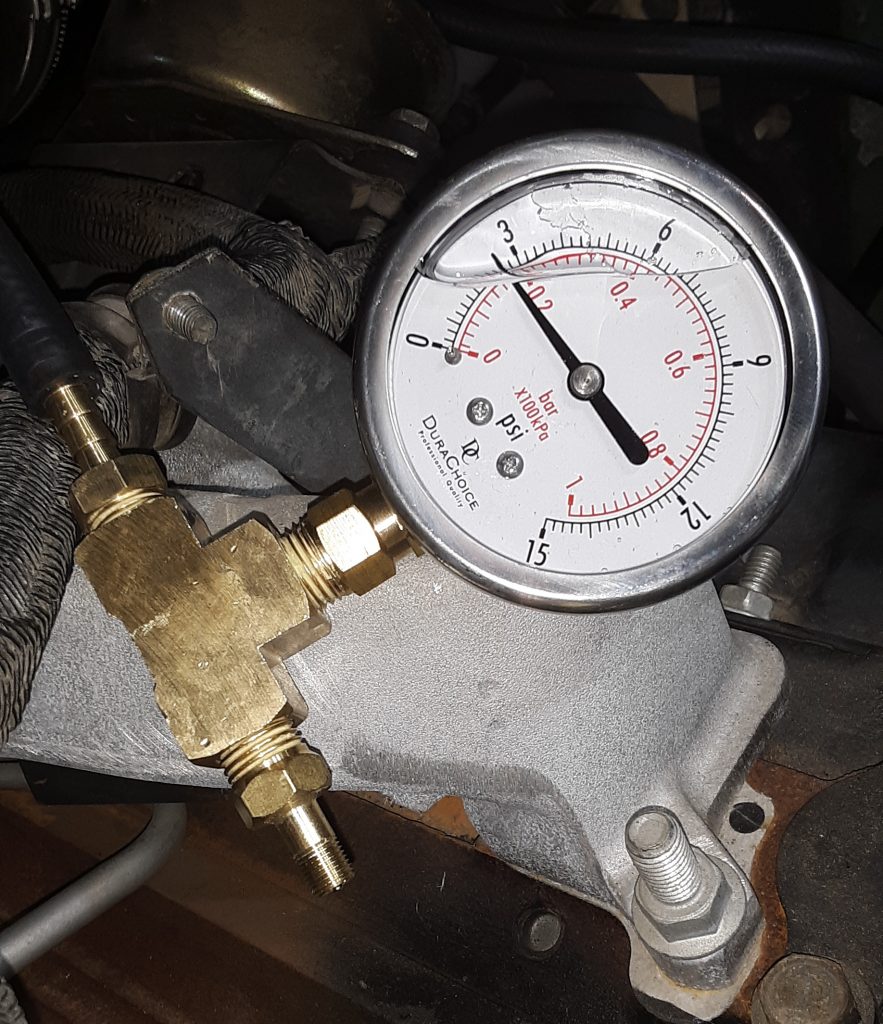

In order to confirm that all Deep Water Fording (DWF) vent lines, transmission seals, differential seals, etc are sealed, a leak down test is required.

Pictured above is a leakdown tester we assembled. We used a 1/4″ NPT brass tee, a 1/4″ NPT x 1/4″ hose barb, a 1/4″ NPT x Schrader valve, and a low pressure gauge (0-15 p.s.i.).

You may note that we used a glycerin-filled gauge. A glycerin-filled gauge adds a level of dampening in an application where shock-loading frequently occurs. It is unnecessary for this application, however the cost was only slightly higher than a non-filled gauge. Of note, filled gauges often have a small brass plug mounted in rubber to allow you to zero the gauge out if atmospheric pressure has raised it from zero.

WARNING AND CAUTION: We highly recommend using a hand pump, such as a bicycle tire pump. Should you put excessive pressure into the system while testing, it is highly likely that you will “blow out” seals, and potentially damage seals in the engine, transmission, gear hubs, and differentials. It takes a very little amount of air to reach 2 to 3 p.s.i., and even use of regulated air may provide a “burp” of air at a pressure sufficient to dislodge or destroy seals.

Most of the cannon plugs (also referred to as Amphenol plugs) had most of their protective anodizing missing. The internal contacts were good and clean. Rather than spend an incredible amount of time and expense of moving the connectors into new fittings, we opted to preserve the exterior of the plug. We use a two-step process of etching primer followed by a lustreless olive drab marketed by Rapco Parts.

The first step is to use a small stainless steel to remove all corrosion from the outside of the plug. The second step is to apply the etching primer and let it fully dry.

Although the etching primer produces a color that is acceptably close to the original anodizing, primer does not make a good final coat.

The final coat of lusterless olive drab (FS 34086) is very close to the original color of the plug, and having a paint coating on the aluminum housing will extend the service life of the connector and assist in preserving the integrity of the electrical connections.

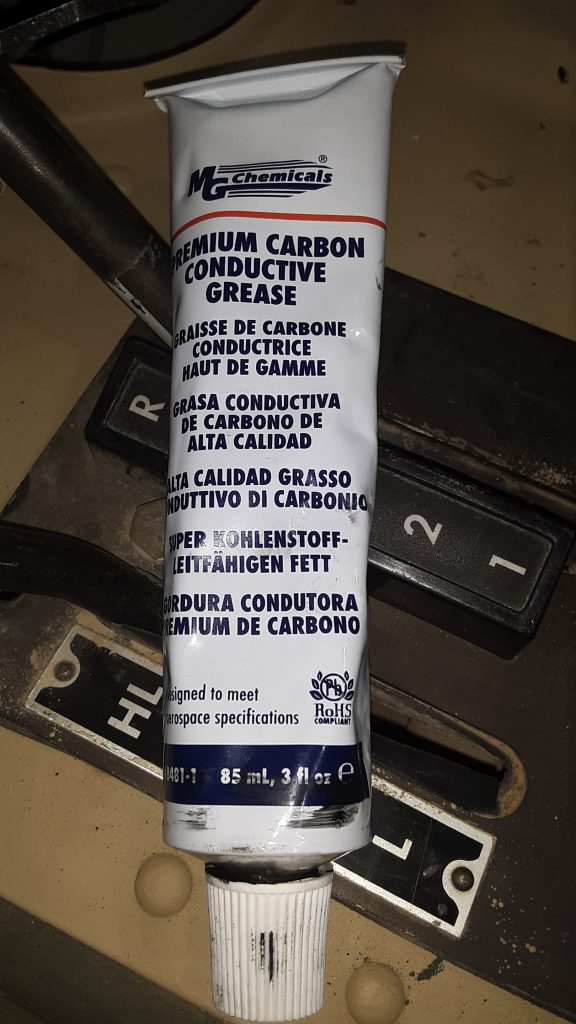

As a note, we applied the silicone grease to the threads and connections to prevent corrosion of the threads and to provide a slight amount of additional waterproofing to the contacts in the event the cannon plug seal fails.

The HMMWV has a reputation for grounding issues. Poor grounding can cause faulty or unreliable gauge readings, and can also cause failure of components including the control box.

We removed and cleaned all connections, and liberally applied carbon grease to all contacts to ensure the best possible connection. After this photo was taken, excess carbon grease was wiped off. This compound is highly conductive, and it is unwise to not clean up after a sloppy application.