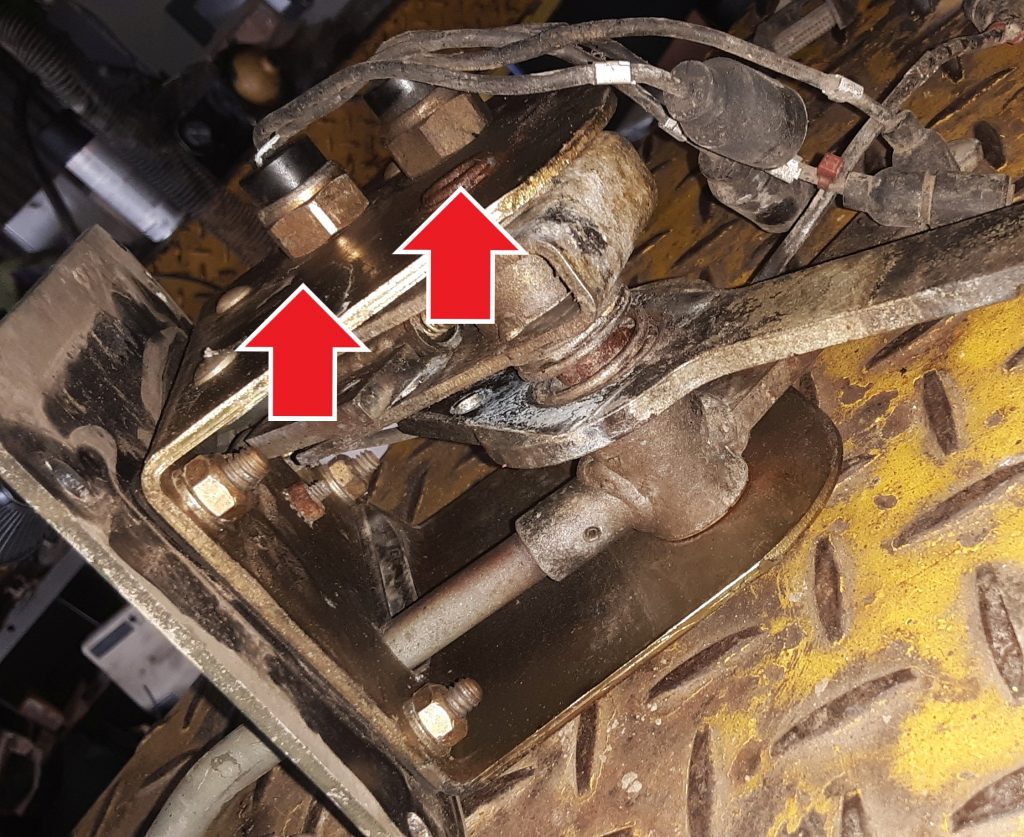

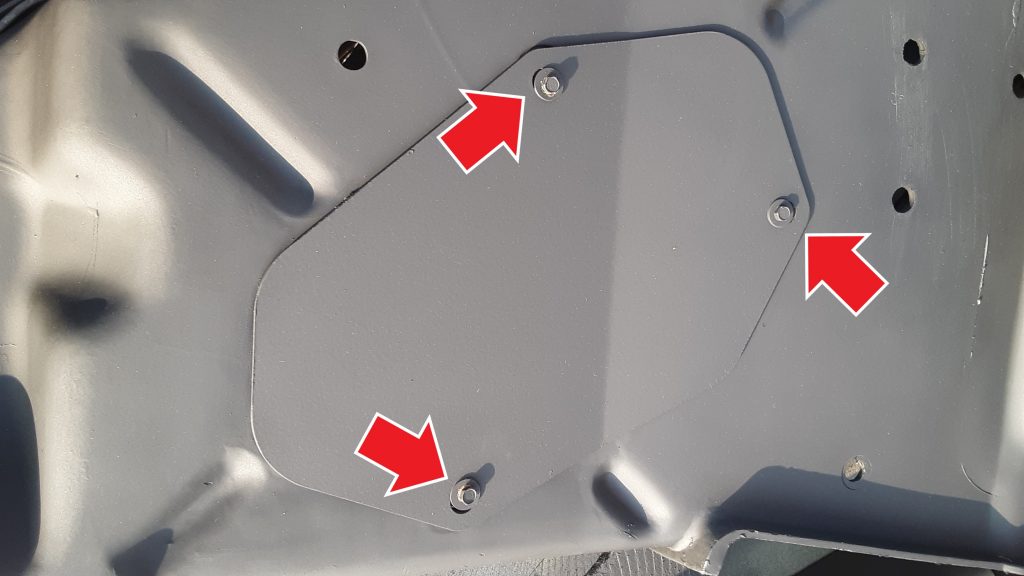

Anytime wiring with rubber boots are involved, it is always best to use a silicone lubricant. This assists in assembling the components, protects the rubber, and provides a further degree of waterproofing.

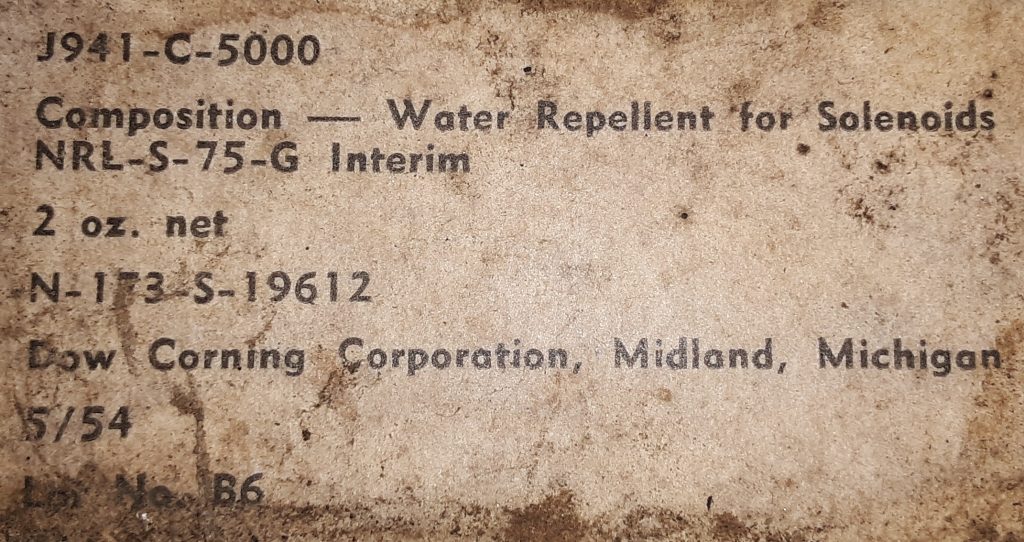

We have almost two cases of military surplus J941-C-5000 (also known as NRL S-75-G), which we acquired in the 1980’s. Since then, we have liberally used the silicone, and despite its age (Manufactured in 1954), it continues to be usable. Not bad for a 65 year old product!

We were unable to find further information of any kind on this product, however we have 30+ years using this material and have had superb results.

UPDATE: NRL S-75-G Interim was developed in World War II as a waterproofing lubricant to prevent machine gun failure caused by moisture freezing in solenoids at high altitudes (-20 F temperatures). (these failures are indicated as affecting the Cal .50 M3 and the 20 mm M24A1 Gun).

“The material is an open chain methyl silicone having a viscosity of 20 cSt at 77°F, and 300 cSt at -65°F, and a pour point of -75°F. Dodecane phosphoric acid (0.1 percent by weight) was added for lubrication. This material was labeled NRL S-75-G Interim.” Per: AMCP 706-26 at page 8-2 (Engineering Design Handbook, Guns Series, Automatic Weapons, Headquarters, U.S. Army Materiel Command, February 1970 [Document unclassified, but not marked as publicly released]).