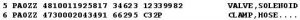

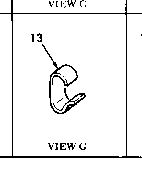

A common problem with standard hose clamps is that they will often tighten up unevenly, cock sideways, and require excessive torque to seal. Here, we have replaced the hose clamps on the transfer case cooling lines with fuel injection clamps (14-16mm range). While these generally cost considerably more than a standard hose clamp, they offer improved sealing and reliability. They can be bulk sourced at a number of online sites, often at a greatly reduced price.

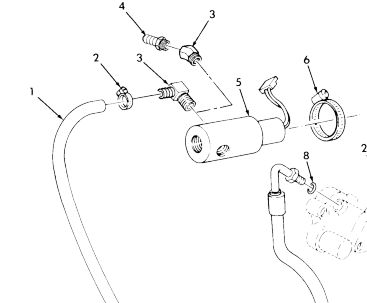

The picture aboves shows where we replaced the original hose clamps 4730-01-118-8278 [4730011188278] with 14-16mm (9/16″-5/8″) fuel injection clamps. The original clamps were apparently installed at the factory from the top side of the frame prior to installing the body. We re-oriented the clamps so that they would be easier to adjust or remove & reinstall from under the vehicle.

These are still the original hoses that came with the powertrain. Although we had new hose to replace it with, we did remove and inspect the hoses. The hose itself remains “live” and showed no sign of cracking, so we retained the original hoses and installed the new clamps.