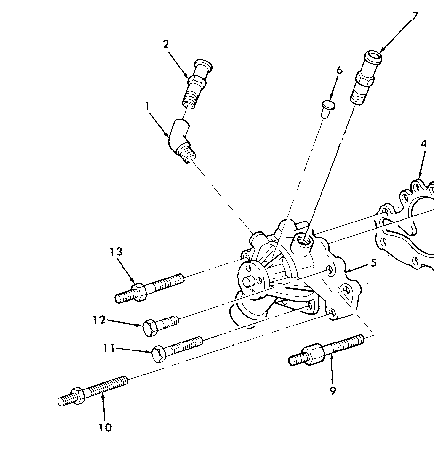

According to the Parts Manual, a rivet is to be installed into the upper weep hole of the water pump. (Fig 31, Item 6).

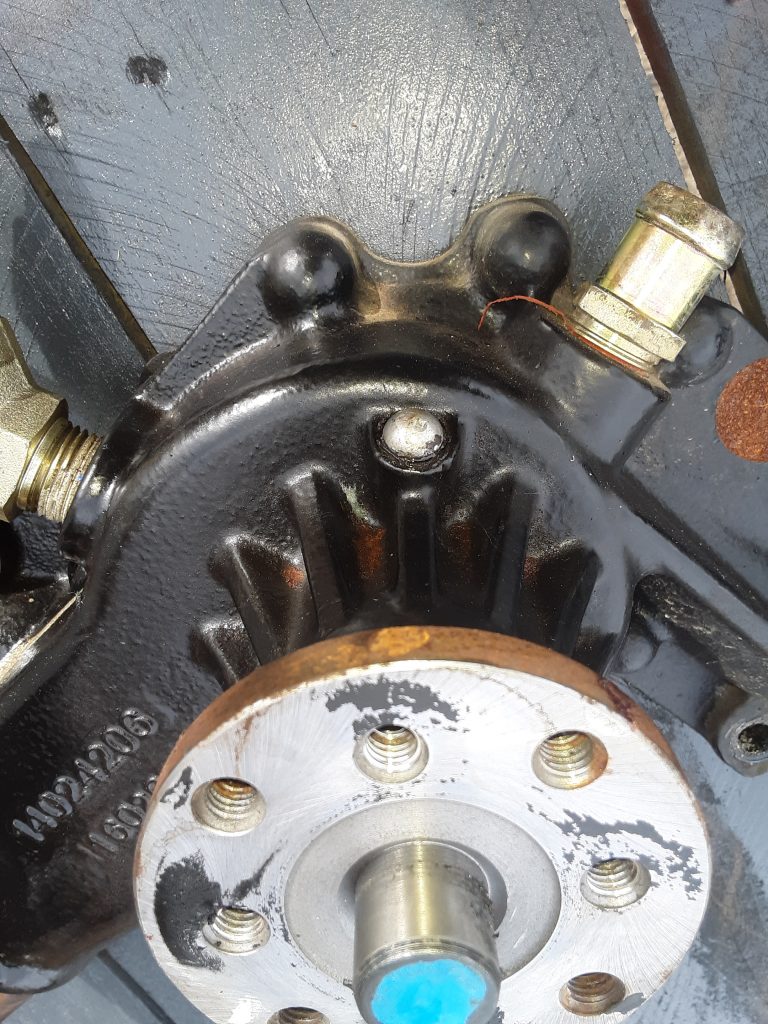

This rivet is 5320-01-218-0721 [5320012180721], and is described as RIVET, SOLID 1/4 X 1/2. This rivet is visible on the water pump we removed from the 6.5 NA. (between the coolant bypass fitting and the heater hose fitting).

Our replacement water pump, as installed, did not have this rivet.

We removed the rivet from the original water pump by prying it out with a screwdriver. It appears that the rivet was held in (or glued in) using Loctite 518 or similar. (“grape jelly”). We noted that the 518 had not set up, either because the engine had not run enough to heat up, or it was simply the wrong material to use.

After removing the rivet, we installed it in our water pump using Permatex No. 2, which does harden up with air, but remains pliable. Although No. 2 has falled into disfavor over the years in place of materials such as RTV and pressure hardening sealants such as Loctite 518, we still find No. 2 suitable (and in some cases, superior) to modern sealants, and especially in this application.

We are unsure of the precise reason as to why the call out requires a rivet to be installed into the water pump. And this may explain the price discrepancy between interchange water pumps and OEM water pumps. In our opinion, moving the rivet from the old pump to the new one (or even buying a new rivet) makes for a considerably less expensive replacement.

I consulted with Tim Grundman of Big Dawg Diesel Worx, LLC, and he informed me that he had never seen a weep hole plugged with a rivet on any industrial or agricultural applications. And although this particular powerplant had not come from a vehicle with the fording upgrades, we speculate that the purpose of plugging the upper weep hole is to prevent contaminants from entering the weep hole and affecting the outer seal on the water pump bearing.

According to our research, this base water pump was used on a number of applications other than the 6.2 and 6.5 diesels. Likely there may have been an application where the water pump mounted upside down from this application, allowing the weep hole to show leakage regardless of position.

Further, it may be that under fording applications, plugging this hole prevents waterborne foreign material from lodging into the front of the water pump and aggravating seal damage.

Regardless of the reason, replacement or purchase and installation of a rivet will keep this water pump as factory designed.